New Buildings / HISAKA WORKS

Plate Heat Exchangers, MGO Coolers, spare parts

PLATE HEAT EXCHANGERS (PHE)

PLATE HEAT EXCHANGERS (PHE)

- Sailing the seven seas Hisaka Plate Heat Exchanger

Hisaka Plate Heat Exchangers are used on a wide variety of ships including tankers and LNG carrier, as well as container ships, pure car carrier and even luxury cruise ships. They are used for "Lubricating Oil Cooler" for main engine, "Fresh Water Cooler" for generator and "Central Cooler" for the main engine and auxiliary equipment.

An ideal PHE integrates four qualities: High efficiency + Low energy + Small space + Maintenance capability.

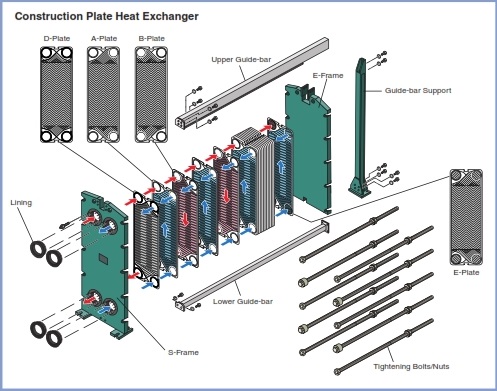

An introduction to the construction and characteristics our top-quality compact PHEs that can be easily maintained.

The heat transfer plates are thin sheets of corrosion resistant metals such as stainless steel or titanium and etc. that are press-formed with a corrugated pattern on their surfaces, and sealed with synthetic rubber gaskets in their groove, which seal the flow channel and direct the fluid into alternate channels.

Such plates are suspended, supported and aligned by guide bars, and tightened by bolts and nuts between fixed and movable frame. The equipped can adjust the number of plates so as to meet the heat duty.

High Performance

The press-formed patterns provide a high heat transfer coefficient over a low heat transfer surface area.

Light Weight and Compact

Thin heat transfer plates and small holding volume allow for a lightweight compact construction that makes installation work easy to perform.

Quick Start-Up

The small holding volume of the heat exchanger allows for rapid operation start-up and highly accurate response capability for changes in operating conditions.

Easy Maintenance

PHEs can be easily cleaned since disassembly is accomplished simply by removing tightening bolts. Reassembly is also performed with ease.

MGO COOLER with Pressure Buffer Device

• Free from plate cracking trouble

• Free from plate cracking trouble

The Pressure Buffer Device protects the PHE from severe pulsation.

• Select optimal thickness of PHE for the operating conditions.

HISAKA can give excellent PHE solutions based on our durability fast data.

• Optimal sizing of Pressure Buffer Device.

HISAKA can also give optimal solutions for Pressure Buffer Device based on our durability test data.

• Reassuring Pressure Buffer Mechanism

When a PHE is used as an MGO COOLER, fracturing of plates due to engine pulsation can be anticipated. If plate fracturing resulted in mixing of the two fluids, the ship might become unable to sail. One method to counter this is duplex structure (double walls) for the plates, which averts mixture of the fluids. However, there is still the risk of plate fracturing due to engine pulsation with this method. Accordingly HISAKA has developed the MGO COOLER, which is equipped with a pressure buffer mechanism to maintain safety.

Our PHE with the Pressure Buffer Device for protection against plate fracturing is optimal for use as an MGO COOLER.